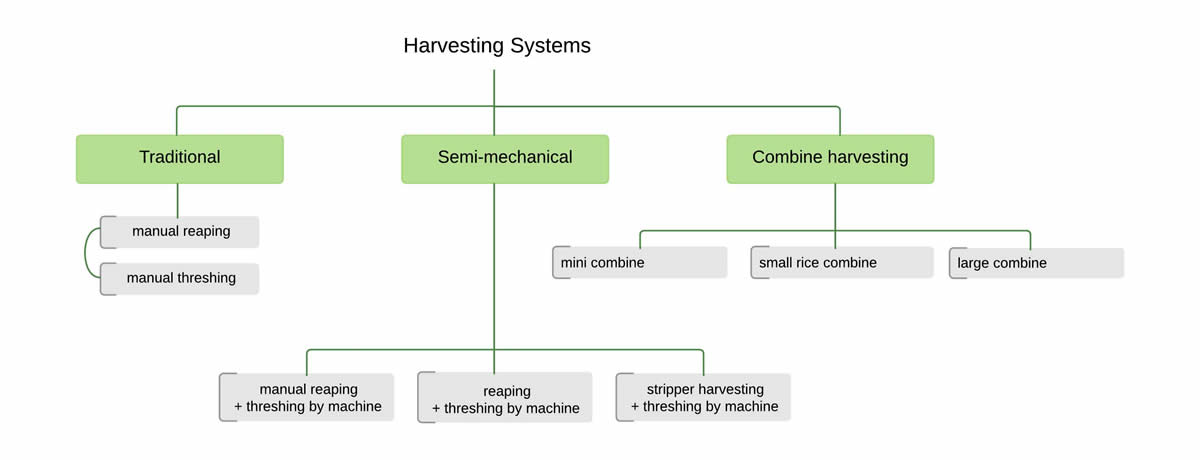

Harvesting systems

Various harvesting systems can be observed in different locations. A wide variety of tools may be used such as knives, sickles, animals, stationary threshing machines, tractor-mounted harvesters, and self-propelled combined harvesters.

The most common systems for paddy harvesting are:

Manual harvesting and threshing

Manual harvesting and threshing

This includes use of traditional tools for harvesting (e.g., sickles, knives) and threshing (e.g., threshing racks, simple treadle threshers and animals for trampling). A pedal thresher is a simple tool to improve manual threshing.

- Semi-mechanical systems, such as

- Manual reaping and mechanical threshing

Manual harvesting is done by hand. The use of portable thresher is usually the first step in mechanical threshing. The use of small stationary machine threshers commonly replaces manual threshing given its high labor requirements. Stationary threshing is generally done in the field, or near the field. - Reaping followed by machine threshing

Cutting and laying the crop on a windrow is done using a reaper, threshing by a thresher, and cleaning either manually or by machine.

- Manual reaping and mechanical threshing

- Combine harvesting

The combine harvester combines all operations: cutting the crop, feeding it into threshing mechanism, threshing, cleaning, and discharge of grain into a bulk wagon or directly into bags. Straw is usually discharged behind the combine in a windrow.

Choosing an appropriate harvesting system depends on a number of factors:

- Availability of labor (manual harvesting is labor-intensive)

- Availability of capital to purchase equipment

- Timeliness of harvesting (how much time is available to complete the harvest)

- Field layout and field accessibility (combine harvesters require a certain field layout and access)

- Rice variety (some varieties are more prone to lodging)

- Demand for quality rice

- Demand for straw (certain threshers damage the straw making it less marketable)

Table: Advantages and disadvantages of using common harvesting systems