|

Milling technology

- Use rubber roll technology for husking

Rubber roll huskers produce the best quality. Engleberg-type or "steel" hullers are no longer acceptable in the commercial rice milling sector, as they lead to low milling recovery and high grain breakage.

Use a paddy separator Use a paddy separator

Separate all paddy from the brown rice before whitening. Paddy separation after husking will lead to better quality milled rice, and reduce overall wear and tear on the rice mill.- Consider two-stage whitening

Having at least two stages in the whitening process (and a separate polisher) will reduce overheating of the grain and will allow the operator to set individual machine settings for each step. This will ensure higher milling and head rice recovery.

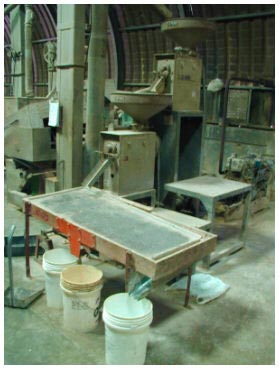

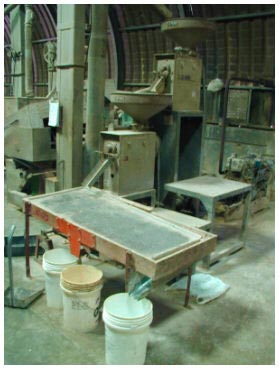

Grade the milled rice Grade the milled rice

Installl a screen sifter to remove small brokens and chips from the polished rice. Rice with a large number of small brokens (or brewer’s rice) has a lower market value. The small brokens can be utilized to produce rice flour.

|

Use a paddy separator

Use a paddy separator Grade the milled rice

Grade the milled rice