Commercial rice milling systems

Commercial milling systems mill the paddy in stages, and hence are called multi-stage or multi-pass rice mills. The objective of commercial rice milling is to reduce mechanical stresses and heat buildup in the grain, thereby minimizing grain breakage and producing uniformly polished grain. Compared to village-level systems, the commercial milling system is a more sophisticated system configured to maximize the process of producing well-milled, whole grains.

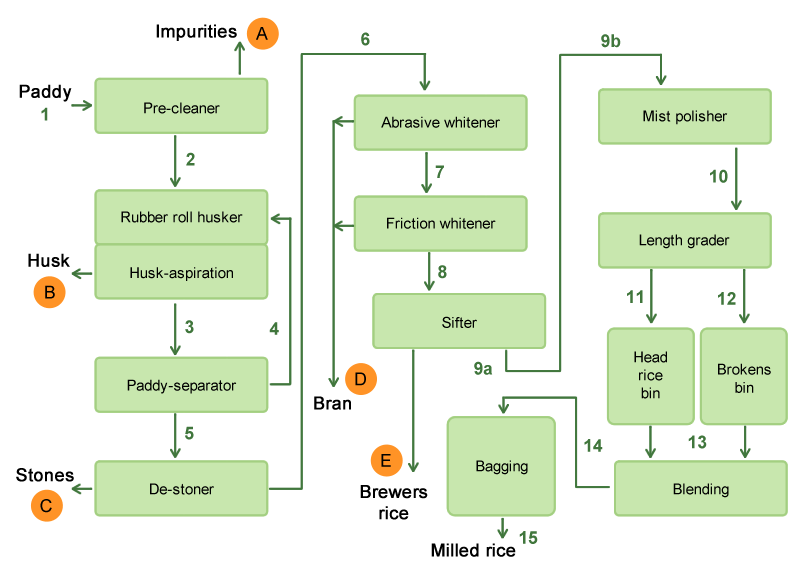

The rice milling facility comes in various configurations, and the milling components vary in design and performance. “Configuration” refers to how the components are sequenced. The flow diagram below shows a modern commercial mill catering to the higher end market. It has three basic stages,

- the husking stage,

- the whitening-polishing stage, and

- the grading, blending, and packaging stage.

In modern rice mills, many adjustments (e.g. rubber roll clearance, separator bed inclination, feed rates) are automated for maximum efficiency and ease of operation. The whitener-polishers are provided with gauges that sense the current load on the motor drives which gives an indication of the operating pressure on the grain. This provides a more objective means of setting milling pressures on the grain.

Objective of commercial milling

A commercial rice miller will have following objectives:

- produce edible rice that appeals to the customer - i.e. rice that is sufficiently milled and free of husks, stones, and other non-grain materials

- maximize the total milled rice recovery out of paddy and minimize grain breakage

Types of commercial mills

- Traditional commercial mill

Traditional commercial mills also consist of different pieces of equipment for the three stages outlined above. They are often made from wood with few metal components and are often driven by a single power source through a system of transmissions. Building such traditional mills was almost considered an art rather than engineering.

- Modern commercial mill

Modern commercial milling lines are fully automated and usually consist of one or more components for each stage of the milling process.

The modern rice milling process

Modern rice milling processes consist of:

| Stage | Function |

| Pre-cleaning | removing all impurities and unfilled grains from the paddy |

| Husking | removing the husk from the paddy |

| Husk aspiration | separating the husk from the brown rice/unhusked paddy |

| Paddy separation | separating the unhusked paddy from the brown rice |

| De-stoning | separating small stones from the brown rice |

| Whitening | removing all or part of the branlayer and germ from the brown rice |

| Polishing | improving the appearance of milled rice by removing remaining ran particles and by polishing the exterior of the milled kernel |

| Sifting | separating small impurities or chips from the milled rice |

| Length grading | separating small and large brokens from the head rice |

| Blending | mix head rice with predetermined amount of brokens, as required by the customer |

| Weighing and bagging | preparing milled rice for transport to the customer |

The indented sheet grader (also called trieur) is a standard piece of equipment in rice processing for length grading of milled rice.

Animation from http://www.muehle-heiligenrode.de/fmtrieur.htm

Flow diagram of a modern rice mill

The flow diagram below represents the configuration and flow in a typical modern rice mill (using the IRRI rice mill as an example).

Description of flow of materials and processes

1 – paddy is dumped in the intake pit feeding the pre-cleaner

A – straw, chaff and empty grains are removed

2 – pre-cleaned paddy moves to the rubber roll husker:

B – husk removed by the aspirator

3 – mixture of brown rice and unhusked paddy moves to the separator

4 – unhusked paddy is separated and returned to the rubber roll husker

5 – brown rice moves to the destoner

C – small stones, mudd balls etc. removed by de-stoner

6 – de-stoned, brown rice moves to the 1st stage (abrasive) whitener

7 – partially milled rice moves to the 2nd stage (friction) whitener

D – Coarse (from 1st whitener) and fine (from 2nd whitener) bran removed from the rice grainduring the whitening process

8 – milled rice moves to the sifter

E – Small brokens/brewer’s rice removed by the sifter

9a – (for simple rice mill) ungraded, milled rice moves to bagging station

9b – (for more sophisticated mill) milled rice moves to the polisher1

10 – Polished rice, will move to length grader

11 – Head rice moves to head rice bin

12 – Brokens moves to brokens bin

13 – Pre-selected amount of head rice and brokens move to blending station

14 – Custom-made blend of head rice and brokens moves to bagging station

15 – Bagged Rice moves to the market

Examples for outputs from the different stages

- Clean paddy after pre-cleaning

Paddy grain after precleaning. Poor quality grain is evident from its darker color. These are immature kernels or half filled grains that are not removed in the precleaner. The presence of poor quality grain lowers the total milling recovery.

- Brown rice at the rubber roller husker

Mixture of paddy grain and brown rice coming out of the rubber roll husker. With uniform size paddy, about 90% of the paddy should be husked after the first pass. This mixture goes through a paddy separator, after which the paddy is returned to the husker,and the brown rice goes to a de-stoner.

- Milled rice after polisher

Milled rice after the 2nd stage friction polisher. Small broken grains are still evident. This product goes to a sifter to remove the small broken grains.

Note: Most mills have several polishing stages for gentle milling. In those mills there is undermilled rice after the 1st stage friction whitener. Not all the bran layers are fully stripped. In times of rice shortage, production of undermilled rice is promoted because of the higher milling recovery.

- Brewers rice from the sifter

Brewer’s rice or small broken grains removed by the screen sifter.