Rice straw

What is rice straw?

Rice straw is a rice by-product produced when harvesting paddy. Each kg of milled rice produced results in roughly 0.7–1.4 kg of rice straw depending on varieties, cutting-height of the stubbles, and moisture content during harvest. Rice straw is separated from the grains after the plants are threshed either manually, using stationary threshers or, more recently, by using combine harvesters (Figure 1).

Figure 1. Harvesting grain and straw using the combine harvester.

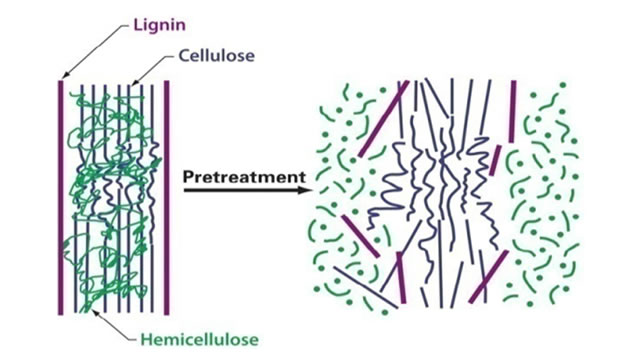

Rice straw, as a lignocellulosic biomass, is comprised of three components: lignin, cellulose, and hemicelluloses. These could be fractionated through pretreatment as shown in Figure 2. Cellulose and hemicelluloses are fiber organics, whereas lignin is the cell wall (Klass 1998).

Figure 2. Major components of lignocellulosic biomass. Source: Klass 1998.

Characteristics of rice straw

Specific weight of uncompressed rice straw is about 70–80 kg/m3 at a moisture content of about 15–18%. Rice straw properties and its ash composition are summarized in Tables 1 and 2, respectively.

Table 1. Rice straw properties.

| HHT MJ kg-1 | Proximate analysis | Ultimate analysis (% weight - dry fuel) | Sources | |||||||

| Fix C | Volatile | Ash | C | H | N | S | Cl | Ash | ||

| 15.09 | 15.86 | 65.47 | 18.67 | 38.2 | 5.2 | 0.87 | 0.12 | 20.26 | Jenkins et al 1998 | |

| 14.57 | 35.94 | 1.18 | 22.00 | Munder 2013 | ||||||

| 14.08 | 33.7 | 4.0 | 1.71 | 0.16 | 0.32 | 29.1 | Guillemot et al 2014 | |||

Table 2. Properties of ash from rice straw.

|

SiO2 |

Al2O3 |

TiO2 |

Fe2O3 |

CaO |

MgO |

Na2O |

K2O3 |

SO3 |

P2O5 |

Sources |

|

74.67 |

1.04 |

0.09 |

0.85 |

3.01 |

1.75 |

0.96 |

12.3 |

1.24 |

1.41 |

Jeng et al 2012 |

|

82.6 |

1.1 |

|

1.0 |

3.3 |

1.7 |

0.3 |

6.3 |

0.9 |

1.7 |

|

The characteristics of rice husk compared with other solid fuels can be summarized as follows:

- High silica content wears out the components in processing machines, such as conveyers or grinders, and hampers digestibility for livestock. Content of volatile matter in rice straw is higher than that in wood and much higher than in coal. On the other hand, fixed carbon is much lower than that in coal. Ash content in rice straw is much higher than that in wood and coal, which causes barriers in energy conversion.

- High content of ash, alkali, and potassium causes agglomeration, fouling, and melting in the components of combustors or boilers.

Typical management options for rice straw

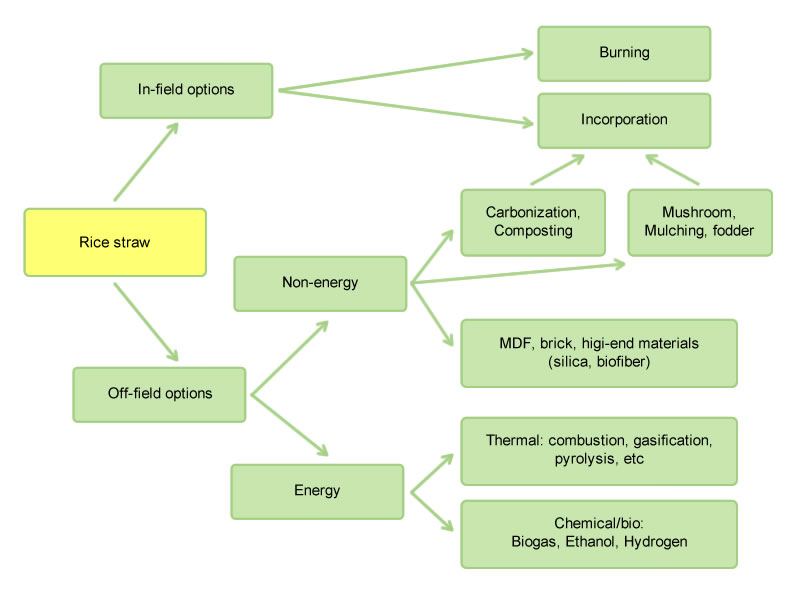

Traditionally, in South and Southeast Asian countries, rice straw and husk are considered as wastes, either dumped into rivers or burned in the field, causing GHG emissions, contamination, and pollution. With the development of recent technologies, rice residues can be processed and managed using better practices. Management options for rice residues can be classified as in-field and off-field management (Figure 3).

Figure 3. Options for rice straw management and use.

References

Guillemot A, Bruant R, Pasquiou V, Boucher E. 2014. Feasibility study for the implementation of two ORC power plants of 1 MWe each using rice straw as a fuel in the context of a public-private partnership with the institutions PhilRice and UPLB. Courbevoie, France: ENERTIME.

Jeng Shiun Lim, Zainuddin Abdul Manan, Sharifah Rafidah Wan Alwi, Haslenda Hashim. 2012. A review on utilisation of biomass from rice industry as a source of renewable energy. Renew. Sust. Energ. Rev. 16:3084–3094.

Jenkins BM. 1998. Physical properties of biomass. In: Kitani O, Hall CW, editors. Biomass Handbook Chapter 5.2. Gordon and Breach, New York.

Klass L. 1998. Biomass for Renewable Energy and Fuels. Entech International, Inc. Barrington, Illinois, United States.

Munder S. 2013. Improving thermal conversion properties of rice straw by briquetting. Master-Thesis. University of Hohenheim.

In-field rice straw management

Learn different strategies to manage rice straw in the paddy soil such as open-field burning and incorporation. Know their advantages and disadvantages, why they should be regulated, and why they must be properly practice.

Off-field rice straw management

With developments in the technologies for its collection and utilization, rice straw is increasingly removed from the fields to be used for better purposes such as for mushroom and energy production and for cattle feed.