Rice husk furnace for grain dryer

Why do we use rice husk for grain dryer furnaces?

Why do we use rice husk for grain dryer furnaces?

Rice husk is cheap and lowers drying cost, thus making mechanical drying competitive. As a waste of the rice milling process, the cost of acquiring rice husk is practically its transportation cost to the dryer.

In Vietnam, 2.5 kg of rice husk yields the same heat quantity of 1 kg of good-grade coal, but the former costs only 1/7 that of the latter.

What are the types of rice husk furnace?

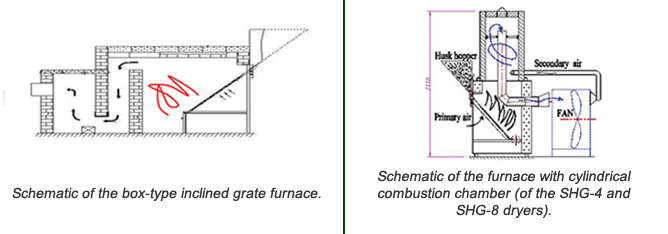

Two furnace designs are shown below, both with inclined grates. The box-type furnace does not do as good a job of settling ashes as the furnace with cylindrical chamber and center pipe.

IRRI, in cooperation with Nong Lam Univeristy (NLU), has recently upscaled the Hohenheim-type inverted draft automatic furnace, which enables each rice husk feeding to last to one whole hour. The burning is even, keeping the drying temperature constant. The furnace can be matched with the SHG-4 four-ton dryer.

Components of a rice husk furnace

Components of a rice husk furnace

- Hopper - to contain rice husk

- Grate - to support the rice husk layer in burning

- Primary combustion chamber - to burn the charred carbon in the husk

- Secondary combustion chamber - to burn the volatile matter (“smoke”) released from the husk

- Ash pit - to contain ash, for periodic removal

Firing a rice husk furnace

- Put a layer of husk on the grate.

- Shut the feeding gate.

- With the dryer fan OFF, use pieces of paper to burn the husk on the grate.

- When enough husk is ignited with the fire visible, turn the fan ON; open the feeding gate.

- Periodically (after about 5 min), check to see if the husk flow is not interrupted; remove the ash if the ash pit is full.

The furnace should burn without smoke or fly ashes.

For more information, contact:

Center for Agricultural Energy and Machinery

Nong-Lam University, Thu-Duc District,

Ho Chi Minh City, Vietnam.

Tel: (++848) 7220725, Fax :( ++848) 8 960 713

E-mail: caem@hcmuaf.edu.vn; phhien@hcm.vnn.vn

For more information:

email postharvest@irri.org; or call +63 2 580 5600