Vietnamese flat-bed dryers SGH4 and SGH8

What is a flat-bed dryer?

What is a flat-bed dryer?

A dryer is a machine that removes the water from wet grains by forcing heated air through the grain bulk. In a flat-bed dryer, the same quantity of grain is kept stationary in a holding bin until drying is completed.

What is the capacity of a flat-bed dryer?

In Southern Vietnam, 3 t/batch is the minimum capacity for economies of scale. On the other hand, 10 t/batch is the maximum size in terms of labor management. Size is selected on the basis of harvest season duration. On average, drying time is 7 h depending on the initial moisture content. Thus, an x t/batch dryer can dry 2.5x t/d, or 100x t per drying season of about 40 days. For example, the 8 t/batch dryer can dry 20 t/d or 800 t per drying season.

Why do we use a flat-bed dryer?

The flat-bed dryer has these features:

- Easy to operate

- Can be used for rice and corn

- Gives better quality grain compared with sun drying

- Simple design allows local production and ensures easy maintenance and repair

- Can be operated with an engine if electricity is not available or is very expensive

How do we operate a flat bed dryer?

- Check oil and fuel levels of the engine, the pulley tension and make sure the dryer is operational. Consult your manual.

- Load the drying bin evenly. If the grain contains lots with different moisture content, mix these well before drying.

- Start the motor or engine.

- For very wet grain, aerating the grains for 30-60 min before drying will improve quality but increase drying time and fuel consumption.

- Start the heater.

- Monitor moisture content and temperature every hour. Stop drying when the moisture content in the middle of the bulk (half grain depth) reaches the desired final moisture content.

Considerations

Thu-Duc District, Ho Chi Minh City, Vietnam

- For seeds drying air temperature should not exceed 43°C

- Increasing the temperature reduces drying time but results in uneven drying.

- Increasing the airflow shortens drying time and reduces moisture content but increases energy cost.

- Mixing during drying reduces the moisture gradient.

Technical specifications

| Drying performance | |

| Capacity | 4 (SHG4) - 8 (SHG8) t/batch |

| Grain depth | 0.25m |

| Drying air temperature | 43 - 45 oC |

| Drying rate | 1.5 % h-1 |

| Drying bin | |

| Usually made of bricks or concrete | |

| Grain floor | |

|

|

| Fan and heater options | |

| Fan | Axial vane type |

| Air delivery 1 | 1 + 0.1 m3 s-1 t-1 |

| Pressure creation | 300 Pa |

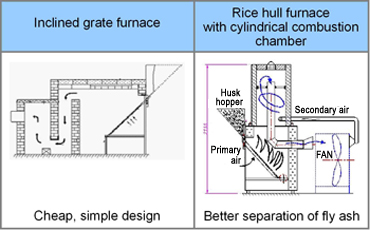

| Rice hull consumption | 6.25 kg h-1 t-1 capacity |

| (One ton of paddy contains approx. 200 kg of rice hull) | |

| Drive options | |

| Diesel engine | 3 hp |

| Fuel consumption | 0.2-0.4 l diesel h-1 t-1 capacity |

| Electric motor | 2 hp |

With information from:

Center for Agricultural Energy and Machinery Nong Lam University, NLU Thu-Duc District, Ho Chi Minh City, Vietnam. Email: phhien@hcm.vnn.vn.

For more information:

email postharvest@irri.org; or call +63 2 580 5600