Vietnamese low cost SRR dryer

What is a low-cost (SRR*) dryer?

What is a low-cost (SRR*) dryer?

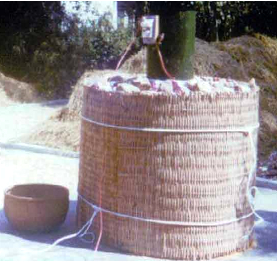

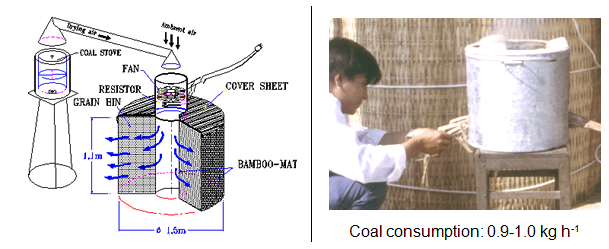

A low-cost dryer is a farm-level dryer that removes water from wet grains by forcing ambient air or slightly pre-heated air through the grain bulk that is stored in a circular bamboo bin. It is a batch dryer—i.e., the same quantity of grain is kept stationary in a holding bin until drying is completed. It is suitable for farmers with small rice fields (~1 ha).

Why do we use an SRR dryer?

The SRR dryer is the only rice dryer that has gained acceptance as a farm-level dryer. It is affordable (costs between $100 and 200) and produces better quality grain than sun drying. It uses the low-temperature drying principle. The SRR dryer is slightly cheaper than the STR dryer and has lower labor requirement, though drying time is much longer.

How do we use the SRR dryer?

Features

- Easy to operate

- Mobile

- Can be used for rice, corn, peanuts and other commodities

- Simple design allows local production and ensures easy maintenance and repair

Operation (electric heater)

During day time (8 am – 6 pm), the fan is turned ON, and the resistor is turned OFF.

First night: With fan ON, the resistor can either be ON or OFF. If the resistor is used, drying time is reduced but energy consumption is higher.

Second night: Both fan and resistors are ON. Without supplemental heat, moisture content of paddy near the inner cylinder might be low enough to be re-wetted by ambient air of high relative humidity.

Third and succeeding nights: Both fan and resistors are turned OFF. Paddy moisture content has been reduced to a level low enough that allows for waiting for the next day to use heat content in the air.

Monitor moisture content and temperature regularly. Stop drying when average moisture content reaches the desired final moisture content.

Considerations

Increasing the temperature reduces drying time but results in uneven drying.

Increasing the airflow shortens drying time and reduces the moisture content but increases energy cost.

Technical specifications

| Drying performance | |

| Capacity | 1 t batch -1 |

| Grain layer | Up to 1 m, depending in capacity |

| Drying air temperature | Ambient temperature and slightly pre-heated air (low-temperature drying), 5- 9 °C above ambient air |

| Drying time | 4 days from 24% to 14% |

| Drying rate | 0.1 % h -1 |

| Drying bin | |

| Circular, made from bamboo mats or wire mesh | |

| Fan and heater options | |

| Fan | Two-stage axial fan made from automotive fan rotors |

| Air volume flow rate | 0.35 m3 s -1 |

| Pressure creation | 350 Pa |

| Electric motor | 0.7 kW |

| Alternative | Electric heater: 1,000 W |

*SRR is a Vietnamese term meaning “Low-Cost”

With information from:

Center for Agricultural Energy and Machinery, Nong Lam University, NLU Thu-Duc District, Ho Chi Minh City, Vietnam. Email: phhien@hcm.vnn.vn

For more information:

Visit the Rice Knowledge Bank website (http://www.knowledgebank.irri.org), email postharvest@irri.org; or call +63 2 580 5600.