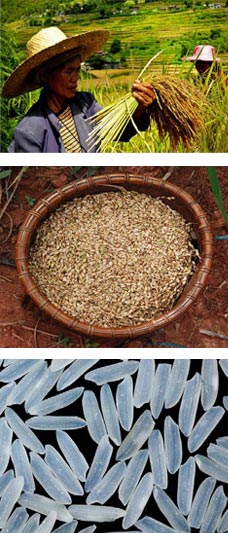

Paddy quality

What determines paddy quality?

What determines paddy quality?

The quality of rice paddy is influenced by variety, environmental weather conditions during crop production, crop production practices, soil conditions, harvesting, and postharvest practices.

What characteristics are used to quantify paddy quality?

Moisture content

Paddy is at its optimum milling potential at 14% moisture content. Grains with high moisture content are too soft to withstand hulling pressure without undue breakage and may be pulverized. Grain that is too dry becomes brittle and has greater breakage during processing.

Degree of purity

Purity is related to the presence of material other than paddy and includes chaff, stones, weed seeds, soil, rice straw, and stalks. Foreign matter in the grain reduces milling recovery and quality of rice, and increases wear-and-tear on milling equipment.

Variety purity

A mixture of varieties causes difficulties at milling and usually results in reduced capacity, excessive breakage, lower milled rice recovery, and reduced head rice.

Grain dimensions

Grain size and shape (length-width ratio) is a very stable varietal property. Long and slender grains normally have greater breakage than short, bold grains and consequently have a lower milled rice recovery.

Cracked grains

Overexposure of mature paddy to fluctuating temperature and moisture conditions leads to development of fissures and cracks in individual kernels. Cracks in the kernel result in reduced milling recovery and head rice yields.

Immature grains

The amount of immature paddy grains in a sample has a major effect on head rice yield and quality. The immature rice kernels are very slender and chalky and are easily broken during milling.

Damaged grains

Paddy deteriorates through biochemical changes in the grain, the development of off-odors, and changes in physical appearance and color. These types of damage are caused by exposure to water, insects, and heat.

Yellowing is caused by overexposure of paddy to wet environmental conditions before it is dried. This results in a combination of microbiological and chemical activities that overheats the grain, whose effects are similar to a mild form of parboiling.

Black spots around the germ end of the brown rice kernel are caused by microorganisms (fungi) and are increased by unfavorable weather conditions. In the process of milling, these black spots are only partly removed, which consequently increases the presence of damaged or unattractive grains.