Machine threshing

The use of small stationary machine threshers commonly replaces manual threshing given the high labor requirements of manual threshing. Stationary threshing is generally done in the field, or near the field.

The use of small stationary machine threshers commonly replaces manual threshing given the high labor requirements of manual threshing. Stationary threshing is generally done in the field, or near the field.

Many stationary threshers for paddy have peg-toothed threshing drums, however threshers fitted with wire-loop or rasp-bars are used as well. Most threshers are of the feed-in type (e.g. entire crop is fed through the thresher) which ensure high throughput.

Hold-on threshers (only panicle is fed into the machine) generally have a lower capacity than feed-in threshers and are primarily used in areas where rice straw is bundled and stored for later use.

Large stationary threshers are fitted with additional cleaning devices such as an oscillating screen, centrifugal blower, and windboard, and threshed grain can be handled without further cleaning.

In many regions, machine threshers are owned by individuals who offer custom operations to farmers. This requires that farmers schedule harvesting dates depending on the availability of the thresher. Many threshers are mounted on trailers or trucks which enables the operator to quickly move from field to field.

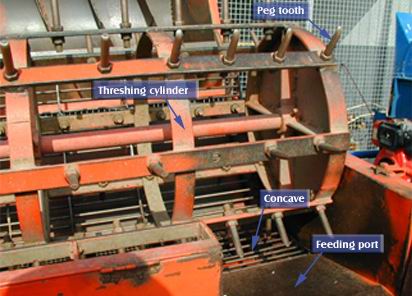

Principle of feed-in type axial-flow thresher

Harvested crop is loaded onto the tray and fed into the opening between the cylinder and the concave at one end of the machine. The pegs on the threshing cylinder hit the material separating the grain from the straw, and at the same time accelerating them around the cylinder.

Harvested crop is loaded onto the tray and fed into the opening between the cylinder and the concave at one end of the machine. The pegs on the threshing cylinder hit the material separating the grain from the straw, and at the same time accelerating them around the cylinder.

The majority of the grain is threshed during initial impact but further threshing is performed as the material moves axially until the straw is discharged at the opposite end. Threshed grain, including impurities such as leaves and short pieces of straw, pass through the openings in the concave and fall on the oscillating screen where large impurities are separated.