Drying

Drying reduces grain moisture content to a safe level for storage. It is the most critical operation after harvesting a rice crop.

Drying reduces grain moisture content to a safe level for storage. It is the most critical operation after harvesting a rice crop.

When rice is harvested, it will contain up to 25% moisture. High moisture level during storage can lead to grain discoloration, encourage development of molds, and increase the likelihood of attack from pests. It can also decrease the germination rate of the rice seed.

It is important to dry rice grain as soon as possible after harvesting— ideally within 24 hours. Delays in drying, incomplete drying or ineffective drying will reduce grain quality and result in losses.

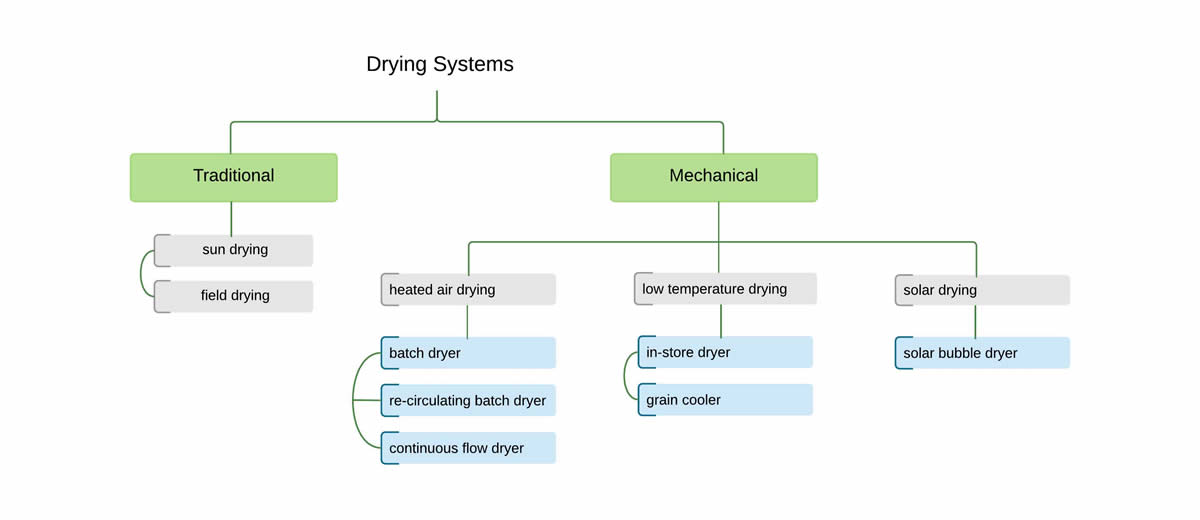

Paddy drying methods include traditional and mechanical systems with varying technological complexity and capacities for either farm or commercial level.

Traditional drying systems

Traditional drying systems are still practiced in many areas because of its low cost and ease of management. These include methods, such as:

- Sun drying - spreading grains under the sun, on mats and pavements

- Mat drying - used in small to medium-scale drying where threshed grain are placed on mats, nets, or canvas

- Pavement drying - often used in large-scale drying for grain collectors and millers, where grains are laid on pavements specifically made for drying

- Field drying and stacking - a method for pre-drying hand-harvested crops before threshing where farmers cut rice panicles in the field and stacked them in small piles on top of the crop stubble

Although field drying and stacking is still practiced in some areas, it is not recommended because it can lead to high losses when grains become overdried and shattered.

Mechanical drying systems

In this system, mechanical dryers are used to remove water from wet grains by forcing either ambient air or heated air through the grain bulk. This is done through:

- Heated air drying - employs high temperatures for rapid drying. The drying process is terminated when the desired final moisture content is reached. It uses the following types of dryer:

- Batch dryer - can be used by farmers, contractors, and small rice mills

- Re-circulating batch dryer - can be used by commercial rice mills and cooperatives

- Continuous flow dryer - not very common, but used by some larger billing enterprises that handle large volumes of wet paddy

- Low-temperature drying or in-store drying - controls the relative humidity rather than the temperature of the drying air so that all grain layers in the deep bed reach equilibrium moisture content. This can be done using the

- In/store dryer - produces very high quality grains but requires long drying time, i.e., four days to two weeks

Read: Heated air drying versus low-temperature drying

- Solar drying - latest drying technology that is able to simulate sun drying even during rainy conditions. This is done through:

- Solar bubble dryer - can be locally-built and used by smallholder farmers

- Grain cooling - cools the grain to safe storage conditions instead of drying it, allowing grains to be conserved for longer periods

Guidelines on proper drying

Proper drying can produce high-quality grains. To do this:

Proper drying can produce high-quality grains. To do this:

- Clean the grains before drying to avoid uneven drying and wet spots.

- Dry paddy grains within 12– 24 hours after cutting as even short-term storage of high moisture grain can cause quality deterioration. Grains should be dried to a certain moisture content (MC) depending on storage period to avoid potential problems:

|

Storage period |

Required MC for safe storage |

Potential problems |

|

weeks to a few months |

14% or less |

molds, discoloration, respiration loss |

|

8–12 months |

13% or less |

insect damage |

|

storage of farmer's seeds |

12% or less |

loss of germination |

|

<1 year |

9% or less |

loss of germination |

Note: The final moisture content depends on the relative humidity of the air that surrounds the grain. For long-term storage of grain and seed in tropical climates, it is crucial to prevent rewetting of grain by humid air.

- Store grains in a safe environment after drying.

- When drying for milling, maintain the MC to 14% so the grain weight and milling yield will not decrease.

- Do not mix grains maintained at different MCs to avoid cracking.

- Always monitor the grain temperature and MC to prevent the grains from being exposed to excess temperatures and over-drying.