Drying

Drying reduces grain moisture content to a safe level for storage. It is the most critical operation after harvesting a rice crop.

Drying reduces grain moisture content to a safe level for storage. It is the most critical operation after harvesting a rice crop.

When rice is harvested, it will contain up to 25% moisture. High moisture level during storage can lead to grain discoloration, encourage development of molds, and increase the likelihood of attack from pests. It can also decrease the germination rate of the rice seed.

It is important to dry rice grain as soon as possible after harvesting— ideally within 24 hours. Delays in drying, incomplete drying or ineffective drying will reduce grain quality and result in losses.

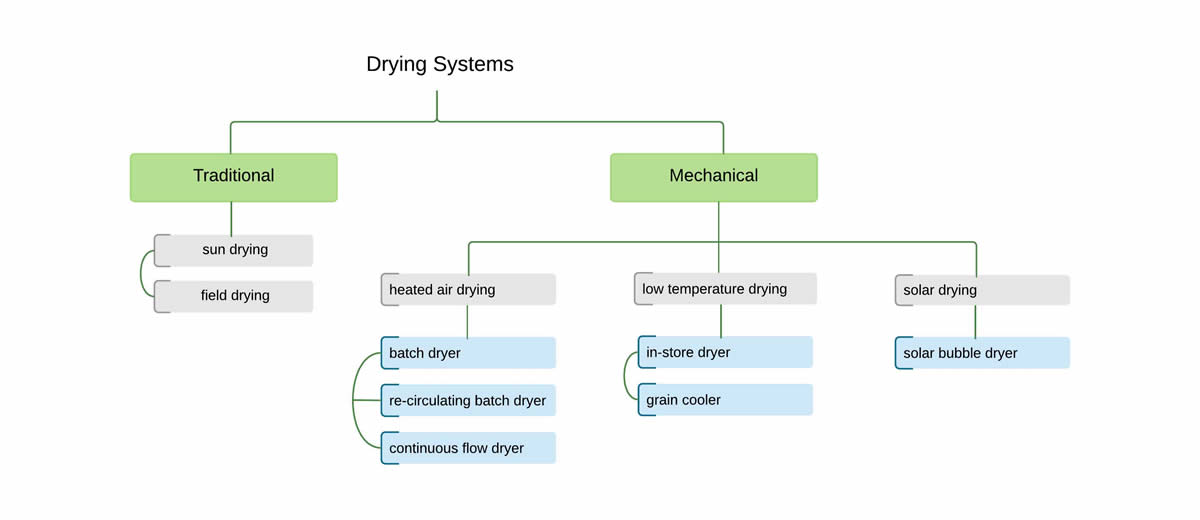

Paddy drying methods include traditional and mechanical systems with varying technological complexity and capacities for either farm or commercial level.

Traditional drying systems

Traditional drying systems are still practiced in many areas because of its low cost and ease of management. These include methods, such as:

- Sun drying - spreading grains under the sun, on mats and pavements

- Mat drying - used in small to medium-scale drying where threshed grain are placed on mats, nets, or canvas

- Pavement drying - often used in large-scale drying for grain collectors and millers, where grains are laid on pavements specifically made for drying

- Field drying and stacking - a method for pre-drying hand-harvested crops before threshing where farmers cut rice panicles in the field and stacked them in small piles on top of the crop stubble

Although field drying and stacking is still practiced in some areas, it is not recommended because it can lead to high losses when grains become overdried and shattered.