Milling

Milling is a crucial step in post-production of rice. The basic objective of a rice milling system is to remove the husk and the bran layers, and produce an edible, white rice kernel that is sufficiently milled and free of impurities.

Milling is a crucial step in post-production of rice. The basic objective of a rice milling system is to remove the husk and the bran layers, and produce an edible, white rice kernel that is sufficiently milled and free of impurities.

Depending on the requirements of the customer, the rice should have a minimum number of broken kernels.

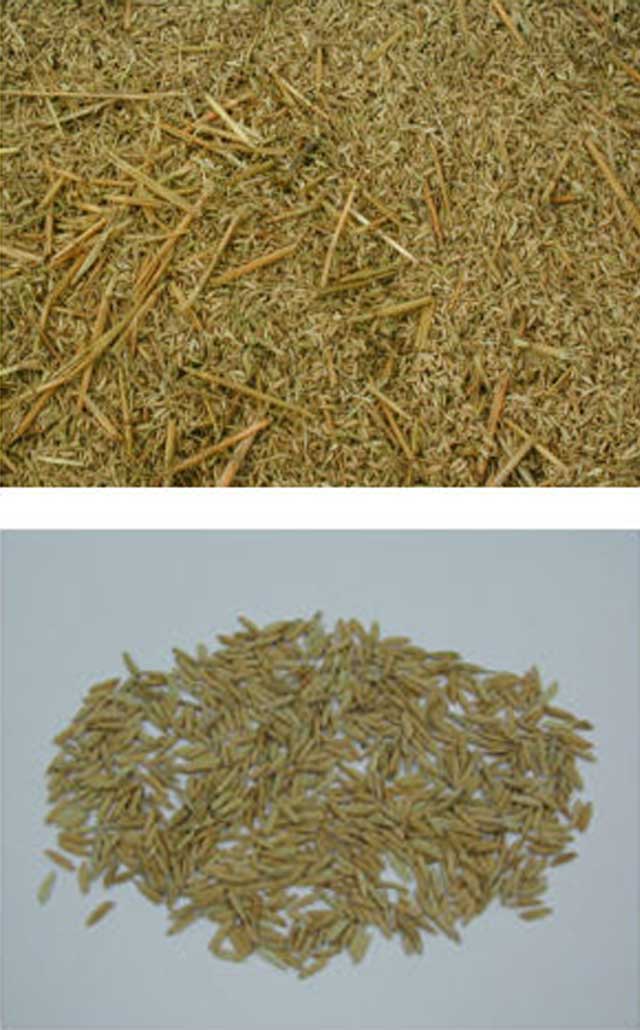

Most rice varieties are composed of roughly 20% rice hull or husk, 11% bran layers, and 69% starchy endosperm, also referred to as the total milled rice.

In an ideal milling process this will result in the following fractions: 20% husk, 8−12% bran depending on the milling degree and 68−72% milled rice or white rice depending on the variety. Total milled rice contains whole grains or head rice, and brokens. The by-products in rice milling are rice hull, rice germ and bran layers, and fine brokens.

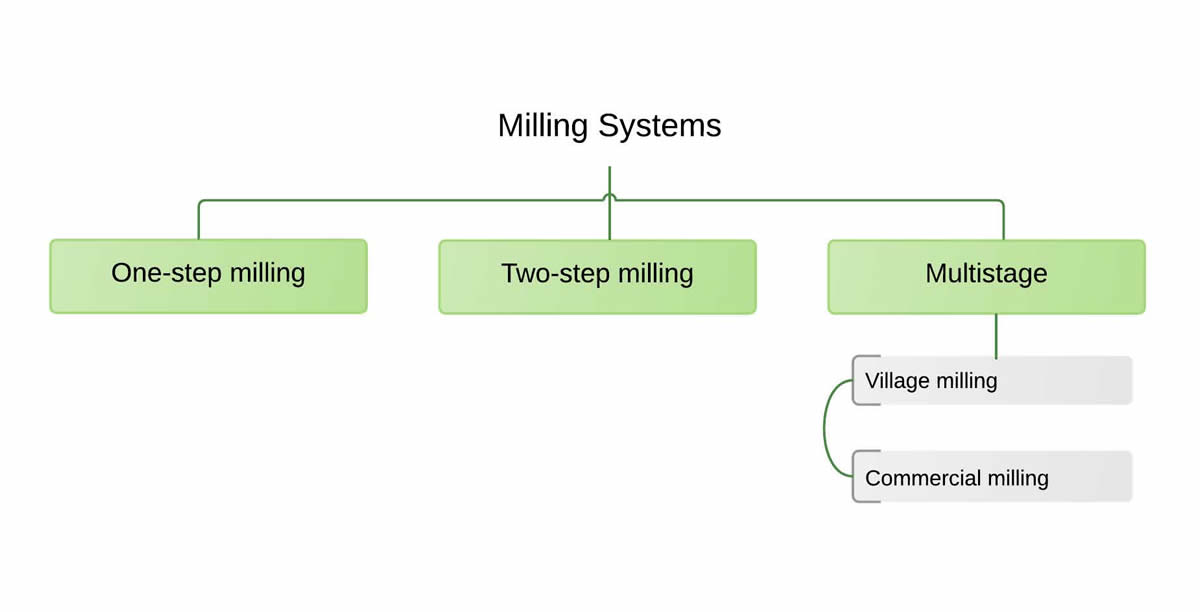

Milling systems

A rice milling system can be a simple one or two step process, or a multi stage process.

A rice milling system can be a simple one or two step process, or a multi stage process.

- One step milling - husk and bran removal are done in one pass

- Two step process - removing husk and removing bran are done separately

- Multistage milling - can be done in the villageor local consumption or commercially for marketing rice; rice undergoes a number of different processing steps, such as:

- Pre-cleaning

- Dehusking or dehulling

- Paddy separation

- Whitening or polishing

- Grading and separation of white rice

- Mixing

- Mist polishing

- Weighing of rice

Guidelines for good milling

The best quality rice will be attained if the quality of paddy is good and the rice is milled properly. To improve the quality of the rice, factors such as the paddy quality and milling technology should be considered.

To obtain good paddy quality:

Mill at the right moisture content (MC)

Mill at the right moisture content (MC)

A moisture content of 14% MC is ideal for milling.

If the MC is too low, high grain breakage will occur resulting in low head rice recovery. Broken grain has only half the market value of head rice. Use a moisture meter to determine the moisture content. Visual methods are not accurate enough.

Pre-clean paddy before husking

Pre-clean paddy before husking

Use of paddy without impurities will ensure a cleaner and higher quality end product.

Different varieties of paddy have different milling characteristics that require individual mill settings. Mixing varieties will generally lead to lower quality of milled rice.

Read: Producing good quality milled rice

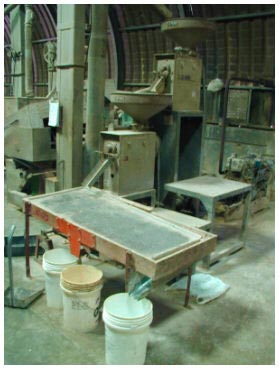

When using milling technology:

- Use rubber roll technology for husking

Rubber roll huskers produce the best quality. Engleberg-type or "steel" hullers are no longer acceptable in the commercial rice milling sector, as they lead to low milling recovery and high grain breakage.  Use a paddy separator

Use a paddy separator

Separate all paddy from the brown rice before whitening. Paddy separation after husking will lead to better quality milled rice, and reduce overall wear and tear on the rice mill.- Consider two-stage whitening

Having at least two stages in the whitening process (and a separate polisher) will reduce overheating of the grain and will allow the operator to set individual machine settings for each step. This will ensure higher milling and head rice recovery.  Grade the milled rice

Grade the milled rice

Installl a screen sifter to remove small brokens and chips from the polished rice. Rice with a large number of small brokens (or brewer’s rice) has a lower market value. The small brokens can be utilized to produce rice flour.

- Monitor and replace spare parts regularly

Turning or replacing rubber rolls, refacing stones, and replacing worn screens regularly will keep milled rice quality high at all times.