Rice husk

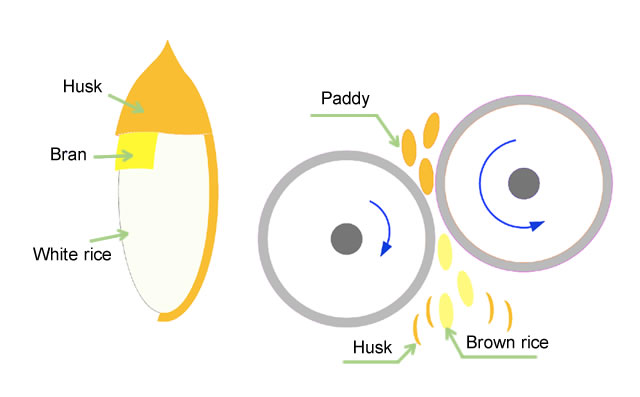

Fig. 1. Paddy grain (left) and its products after husking.

What is rice husk and what are its major products?

The rice husk, also called rice hull, is the coating on a seed or grain of rice. It is formed from hard materials, including silica and lignin, to protect the seed during the growing season. Each kg of milled white rice results in roughly 0.28 kg of rice husk as a by-product of rice production during milling.

Common products from rice husk are: solid fuel (i.e., loose form, briquettes, and pellets), carbonized rice husk produced after burning, and the remaining rice husk ash after combustion.

Rice husk in its loose form (Fig. 2) is mostly used for energy production, such as combustion and gasification. Combustion is the process of burning carbon in the rice husk, which emits CO2 and generates heat energy for further use. One of the most efficient uses of this by-product is its direct combustion without the need for a heat exchanger with a proper furnace to generate heat for drying paddy. Gasification is the process of converting rice husk to synthesis gas (syngas) in a gasifier reactor with a controlled amount of air. Syngas can be used as fuel for drying and cooking or in a cogeneration system to produce electricity.

Rice husk briquettes (Fig. 3) and pellets(Fig. 4) are produced using densification to increase the density of materials and their combustion performance. These densified rice husks are mainly used in industrial boilers as a substitute for fossil fuel.

Rice husk ash (Fig. 5) is the remaining by-product after combustion is done. The amount of carbon remaining in ash depends on the combustion performance (i.e., complete or incomplete combustion). Rice husk ash can be used as a soil amendment and as additive in cement and steel, among others. However, only small amounts compared to the total rice husk production are used for such purposes.

Carbonized rice husk (Fig. 6) is produced by thermal decomposition of the rice husk under a limited supply of oxygen (O2) and at relatively low temperatures (less than 700°C). Biochar produced from carbonization can be used as soil amendment, for processing fertilizer, and as activated carbon, etc.

Characteristics of the rice husk

Produced during rice milling, the rice husk is already dried and accumulated at the factory. The specific weight of uncompressed rice husk is about 100 kg/m3. Average properties of rice husk in proximate analysis a and ultimate analysis b are shown in Tables 1 and 2, respectively, according to various research on the rice husk by Beagle (1978), Jeng et al. (2012), and Jenkins (1998).

Table 1. Rice husk composition in % of weight (dry basis) based on proximate analysis.a

|

Fixed carbon (%) |

Volatile matter (%) |

Ash (%) |

|

15 |

67 |

18 |

a. Proximate analysis is a partitioning of compounds in a feed into six categories based on the chemical properties of the compounds. The six categories are: moisture, ash, crude protein, crude lipid, crude fiber, and nitrogen-free extracts (digestible carbohydrates) (Aquaulture, accessed 2016).

Table 2. Compositions of rice husk in % of weight (dry basis) based on ultimate analysis.b

|

C |

H |

O |

N |

S |

Ash |

HHV |

|

40 |

5 |

34.8 |

0.8 |

0.1 |

19.5 |

14.8 |

b. The determination of the percentage of elements contained in a chemical substance (Encyclopedia, accessed 2016)

Silicon oxide forms the main component of the ash with trace amounts of Al2O3, Fe2O3, CaO, MgO, K2O, and Na2O. The physical and chemical properties of rice husk ash are dependent on the components of the combustion process, such as combustion type, feeding type, temperature, residence time, and availability of oxygen (aerobic or anaerobic).

The characteristics of rice husk compared with other solid fuels can be summarized as follows:

- Its high silica content causes excessive wear to parts of processing machines, such as conveyors or grinders, and hampers digestibility in livestock. The content of volatile matter in the rice husk is higher than in wood and much higher than in coal; whereas, fixed carbon is much lower than in coal. Ash content in the rice husk is much higher than in wood and coal, which causes barriers in energy conversion.

- The high content of ash, alkali, and potassium causes agglomeration, fouling, and melting of the parts of combustors or boilers.

Utilization of the rice husk

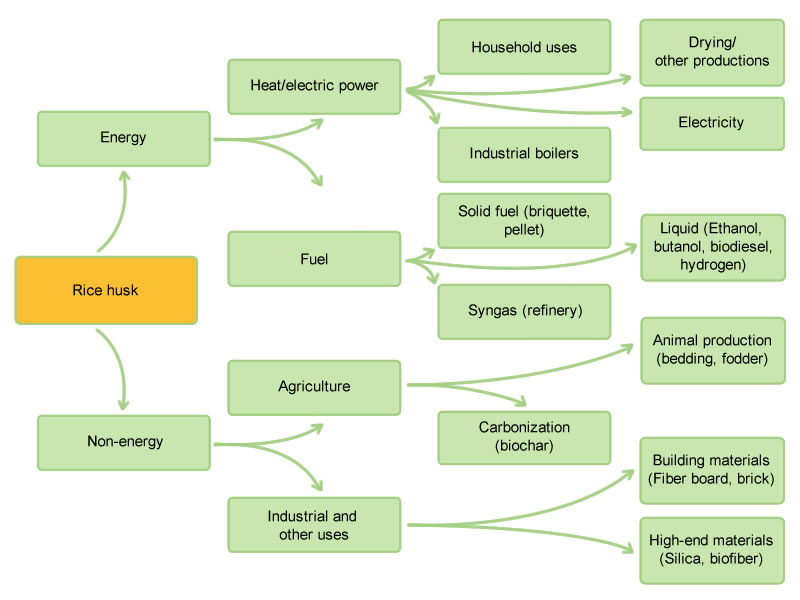

Rice husk was long considered a waste from the rice milling process and was often dumped and/or burned. But because it can be easily collected and is cheap, some amount of rice husk has always been used as an energy source for small applications, such as for brick production, for steam engines and gasifiers used to power rice mills, and for generating heat for rice dryers. The high silica content of rice husk ash makes it a good additive for the steel and concrete industries. To a lesser degree, rice husk ash is used as soil conditioner, activated carbon, insulator, and others. More recently, creation of electrical power on a small to medium scale—up to 5 megawatts—has been piloted throughout Asia, with some promising approaches but also some demonstrated limits. Failure was mostly due to feedstock supply problems once the formerly free waste rice husk becomes a traded commodity and due to logistical problems and the high cost when transport distances become too large. A diagram of rice husk use is shown in Figure 1 below.

Fig. 1. Options for the use of rice husk.

References

Beagle E.C., 1978. Rice husk conversion to energy. FAC Agricultural services Bulletin No 31, Rome.

Jeng Shiun Lim, Zainuddin Abdul Manan, Sharifah Rafidah Wan Alwi, Haslenda Hashim. 2012.

Jenkins BM, 1998. Physical properties of biomass. In biomass Handbook, Chap.5.2, O. kitani and C. W. Hall, Gordon and Breach, New York.

Aquaulture, accessed 2016. http://www.aquaculture.ugent.be/Education/coursematerial/online%20courses/ATA/analysis/proxi.htm

Encyclopedia, accessed 2016. http://encyclopedia2.thefreedictionary.com/Ultimate+analysis