Rice husk pelletizing and briquetting

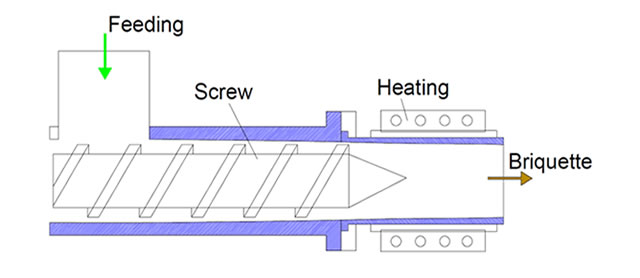

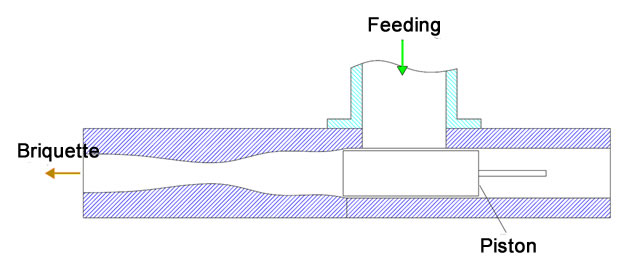

Briquetting and pelletizing rice husk is to increase the density of feedstock. Basically, machines that produce briquettes and pellets could be classified into three types: the screw extruder (Fig. 1), the piston (Fig. 2), and the ring die (Fig. 3).

Fig. 1. Schematic structure of the screw extruder for briquetting.

Fig. 2. Schematic structure of a piston-type briquetting machine.

Fig. 3. Schematic structure of a ring die-type pelletizing machine.

Rice husk pellets and briquettes have a density of about 500 to 600 kg per cubic meter, 5 times that of their loose form. This increase in density leads to a reduction in transportation cost and increase in the performance of energy conversion processes. The advantages of using rice husk briquettes and pellets recently stimulate a fast growth of these business models in rice production.