Harvesting processes

Harvesting rice consists of the basic operations which can be done in individual steps or in combination using a combine harvester. These include:

- Reaping - cutting the mature panicles and straw above ground

- Threshing - separating the paddy grain from the rest of cut crop

- Cleaning - removing immature, unfilled, non-grain materials

- Hauling - moving the cut crop to the threshing location

- Field drying - leaving the cut crop in the field and exposing it to the sun for drying (optional)

- Stacking/piling - temporarily storing the harvested crop in stacks or piles (optional)

- Bagging - putting the threshed grain in bags for transport and storage

Traditional harvesting activities such as field drying and stacking/piling are not recommended because they can lead to rapid quality deterioration and increased harvest losses.

Besides these, a variety of other activities can be included in harvesting such as gathering, reaping (gathering standing grain by cutting), bundling, and various forms of transporting the crop and grain.

Harvesting systems

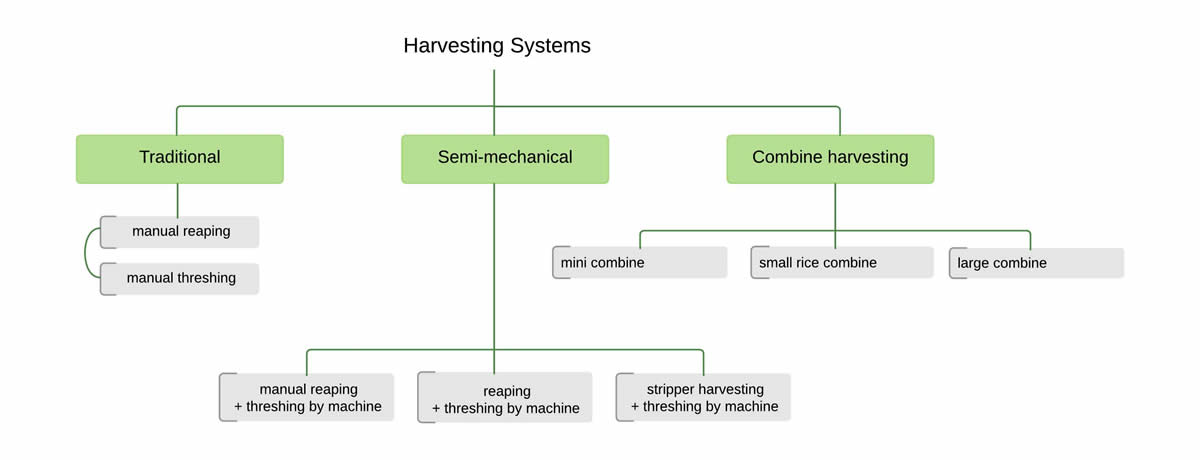

Click to zoomHarvesting systems vary from region to region. A wide variety of traditional and semi-mechanical tools, or combine harvesters may be used.

The most common harvesting systems are:

- Manual harvesting and threshing

- uses traditional tools such as sickles, knives, threshing racks, simple treadle threshers, and animals for trampling

- Manual reaping and mechanical threshing

- manual harvesting by hand; uses portable thresher or small stationary machine threshers

- Reaping followed by machine threshing

- uses a reaper, threshing by a thresher, and cleaning either manually or by machine

- Combine harvesting

- combines all processes: reaping, threshing, and cleaning

Read more »

Guidelines on proper harvesting

Regardless of the harvesting system used, it is important to ensure that good grain quality is preserved during harvest operations and harvest losses are kept to minimum.

To properly harvest your crops, make sure to:

- Harvest at the right time with the right moisture content.

- Correct timing is crucial to prevent losses and ensure good grain quality and high market value. Grain losses may be caused by rats, birds, insects, lodging, and shattering.

- Harvesting too early results in a larger percentage of unfilled or immature grains, which lowers yield and causes higher grain breakage during milling.

- Harvesting too late leads to excessive losses and increased breakage in rice.

- Harvest time also affects the germination potential of seed.

When to harvest

When to harvestDepending on the growth duration of the variety, harvesting time should be around 110−120 DAS for direct seeded rice, and 100−110 DAT for transplanted rice.

To determine if the crop is ready for harvest, check for the following indicators:

- Moisture content

Grain moisture content ideally is between 20 and 25% (wet basis). Grains should be firm but not brittle when squeezed between the teeth.

Harvest at minimal surface moisture (e.g. from previous rainfall or early morning dew).

Read: Measuring moisture content in harvesting

- Ripe grains per panicle

Harvesting should be done when 80−85% of the grains are straw colored (i.e., yellow-colored).

- Number of days after sowing

Generally the ideal harvest time lies between 130 and 136 days after sowing for late-maturing variety, 113 and 125 for medium duration, and 110 days for early-maturing varieties.

- Number of days after heading

For dry season harvesting, an optimum time is 28−35 days after heading (emergence of panicle tip from leaf sheath). In wet season harvest, optimum time is 32−38 days after heading.

- Avoid delays in threshing after harvesting.

Threshing should be done as soon as possible after cutting to avoid rewetting and to reduce grain breakage.

- Use proper machine settings when using a threshing machine.

- Clean the grains properly after threshing.

- Dry the grains immediately after threshing.

Read: Health and safety precautions during harvesting

Harvesting is the process of collecting the mature rice crop from the field. Paddy harvesting activities include reaping, stacking, handling, threshing, cleaning, and hauling. These can be done individually or a combine harvester can be used to perform the operations simultaneously.

Harvesting is the process of collecting the mature rice crop from the field. Paddy harvesting activities include reaping, stacking, handling, threshing, cleaning, and hauling. These can be done individually or a combine harvester can be used to perform the operations simultaneously. Harvesting rice consists of the basic operations which can be done in individual steps or in combination using a combine harvester. These include:

Harvesting rice consists of the basic operations which can be done in individual steps or in combination using a combine harvester. These include:

When to harvest

When to harvest