Milling

Milling is a crucial step in post-production of rice. The basic objective of a rice milling system is to remove the husk and the bran layers, and produce an edible, white rice kernel that is sufficiently milled and free of impurities.

Milling is a crucial step in post-production of rice. The basic objective of a rice milling system is to remove the husk and the bran layers, and produce an edible, white rice kernel that is sufficiently milled and free of impurities.

Depending on the requirements of the customer, the rice should have a minimum number of broken kernels.

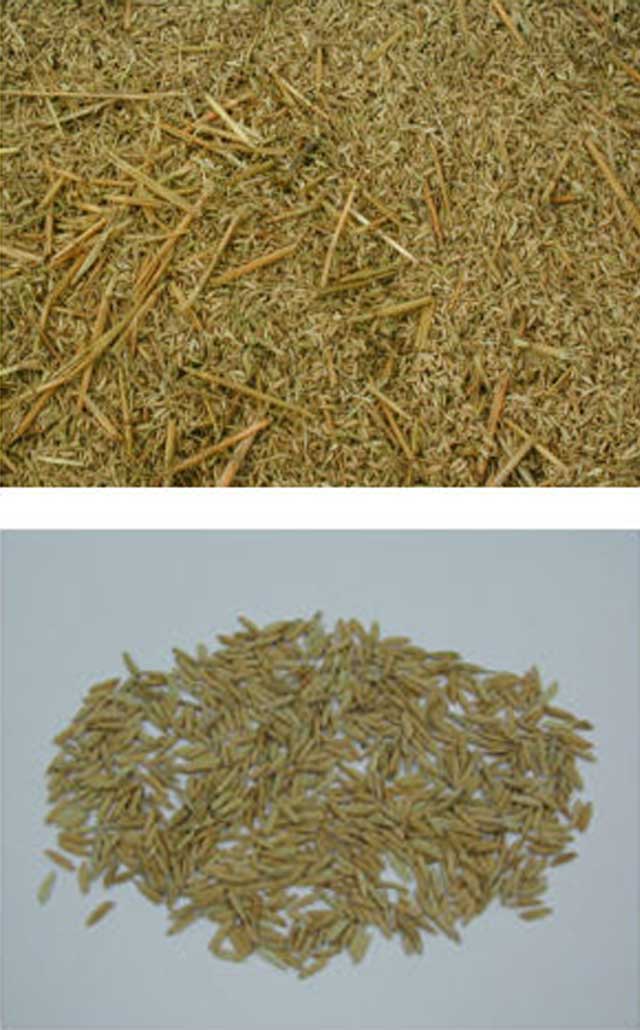

Most rice varieties are composed of roughly 20% rice hull or husk, 11% bran layers, and 69% starchy endosperm, also referred to as the total milled rice.

In an ideal milling process this will result in the following fractions: 20% husk, 8−12% bran depending on the milling degree and 68−72% milled rice or white rice depending on the variety. Total milled rice contains whole grains or head rice, and brokens. The by-products in rice milling are rice hull, rice germ and bran layers, and fine brokens.

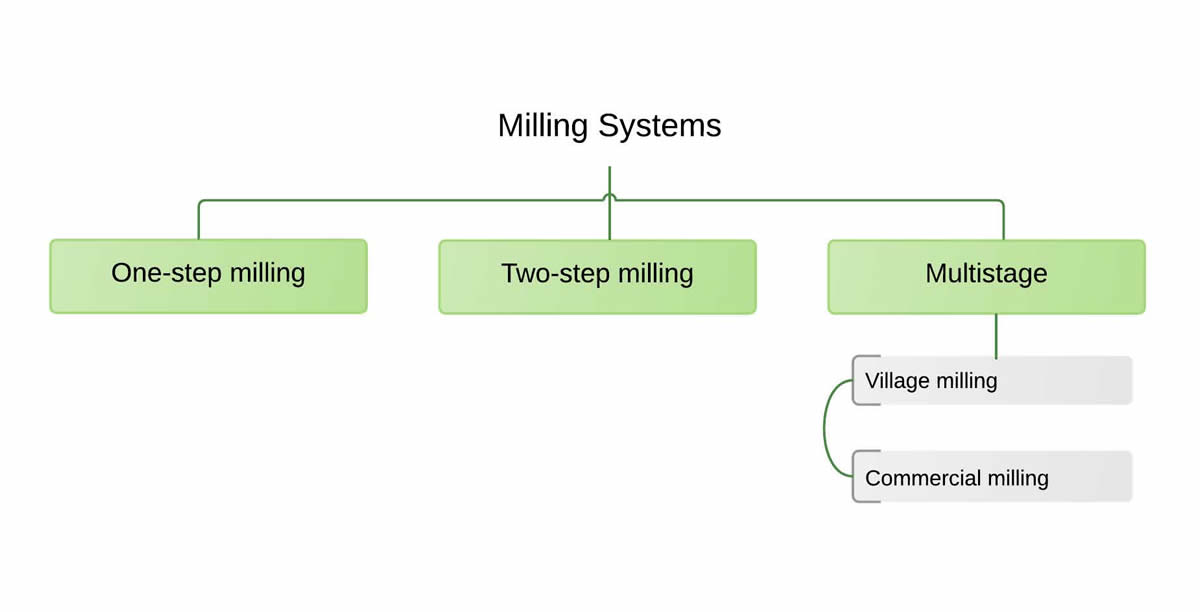

Milling systems

A rice milling system can be a simple one or two step process, or a multi stage process.

A rice milling system can be a simple one or two step process, or a multi stage process.

- One step milling - husk and bran removal are done in one pass

- Two step process - removing husk and removing bran are done separately

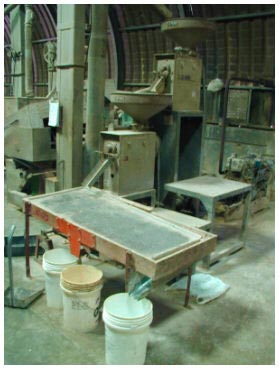

- Multistage milling - can be done in the villageor local consumption or commercially for marketing rice; rice undergoes a number of different processing steps, such as:

- Pre-cleaning

- Dehusking or dehulling

- Paddy separation

- Whitening or polishing

- Grading and separation of white rice

- Mixing

- Mist polishing

- Weighing of rice

Mill at the right moisture content (MC)

Mill at the right moisture content (MC) Pre-clean paddy before husking

Pre-clean paddy before husking Use a paddy separator

Use a paddy separator Grade the milled rice

Grade the milled rice