Gasification of rice husk

Gasification is the process of converting rice husk to synthesis gas (syngas) in a gasifier with controlled amount of air. Syngas can be used as a heat source for drying, cooking, etc., or in a cogeneration system for producing electricity.

The gasification process can be described in two steps. Step 1 is pyrolysis, which involves heating the rice husk at 500°C with no or limited air to produce gases, tar, oil, and char (carbonized husk). The gas generated from Step 1 is gasified at about 1,000°C in Step 2 to produce syngas or producer gas. These gases can be used to generate heat or electricity or to produce refined synfuel.

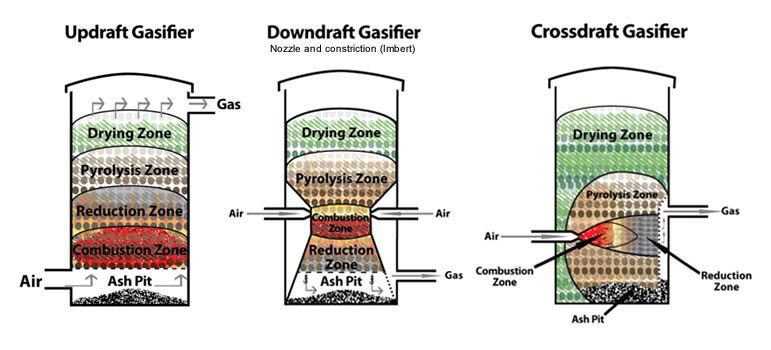

Fixed-bed gasifiers in principle are classified in updraft, downdraft, and cross-draft types as shown in Figure 1 (http://www.gekgasifier.com).

Fig. 1. Different moving-bed gasifier principles. Source: http://www.gekgasifier.com

Using rice husk at the rice mill for gasification to generate electricity, and supplying this power for rice processing is seen as a potential for low-cost electricity production. Hence, this technology is quite common in Myanmar and, recently, in Cambodia also. However, the main problem with power generation from rice husk gasification is environmental pollution. For example, the current investment rate of a small-scale rice husk gasifier in Cambodia (Fig. 2a) can reach up to USD 400 per kW of power. The use of water for gas cleaning (Fig. 2b), which is about 2 liters per kWh generated, is still a major pollution source. Furthermore, tar load that form during the pyrolysis stage of gasification of biomass feedstock is known to be highly carcinogenic and can reduce the efficiency of machinery parts.