Rice husk furnace

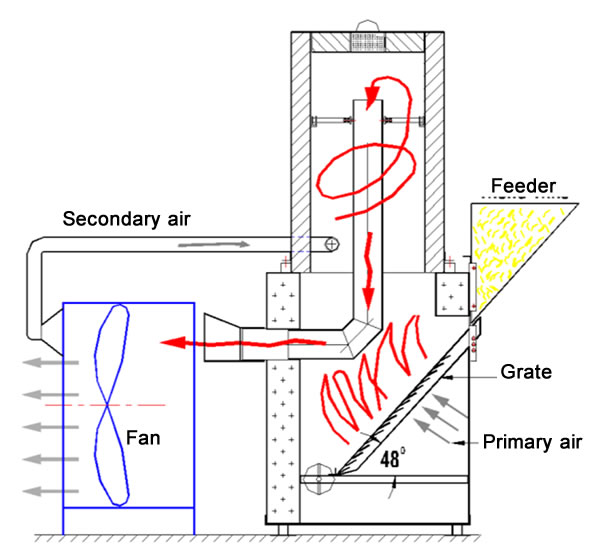

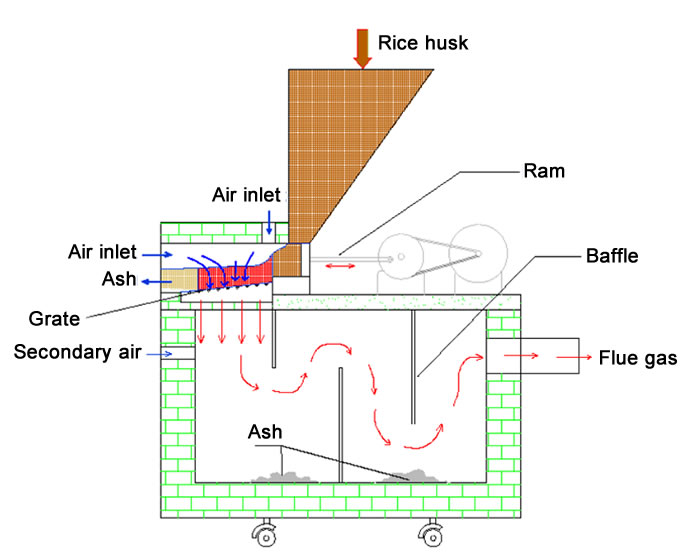

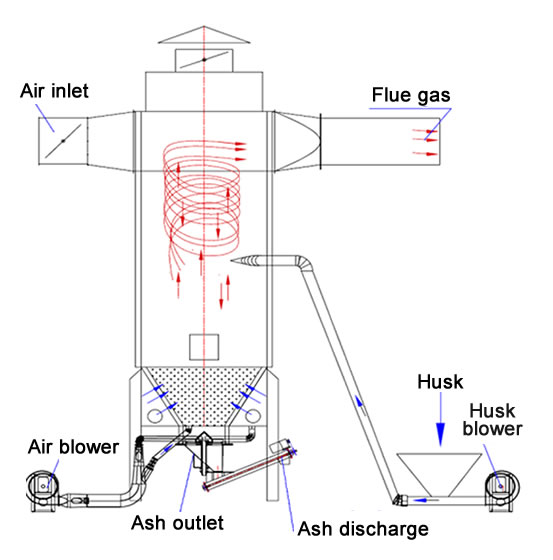

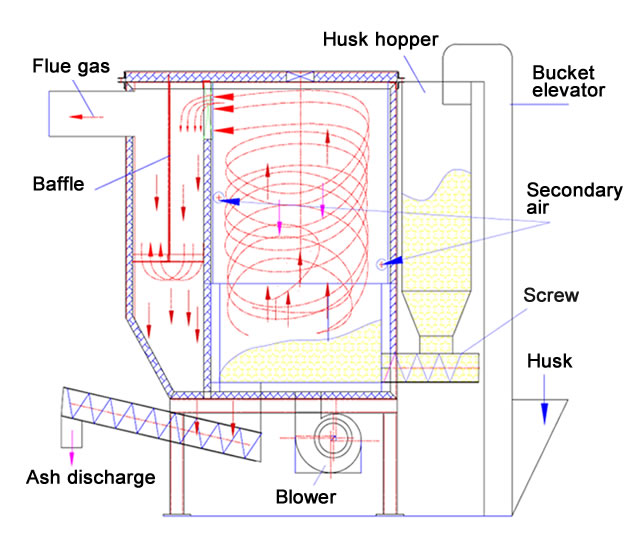

The first rice husk furnaces were reported in scientific literature around 100 years ago. It was used in a rice mill in Myanmar as fuel of the boiler that created steam used for powering a rice mill with a steam engine (International steam, 2015; How steam engine work, 2015). Rice husk furnaces, such as the inclined grate manual-fed furnace and the automatic non-grate furnace, have been researched and developed in recent years. The rice husk furnace is selected based on efficiency, quality of flue gas (clean), heat capacity, nature of operation (manual or automatic), investment cost, and energy cost. There are two types of rice husk furnaces that are popularly used in Southeast Asian countries, which are small-scale in nature. These are the inclined grate furnace with a cylindrical combustion chamber (Fig. 1, Nguyen et al 1996) and the downdraft rice husk furnace (Fig. 2, Gummert et al 2007). In large-scale applications, continuously fed furnaces are preferred. There are two typical examples of this type of furnace: the cyclone combustion furnace (Fig. 3, Nguyen et al 2012) and the IRRI-NLU non-grate furnace developed by the ADB-IRRI postharvest project (Fig. 4, Tran et al 2013). A comparison of these furnaces is summarized in Table 1 based on assessments in 2013.

|

|

| Fig. 1. Rice husk furnace with inclined grate and cylindrical combustion chamber | Fig. 2. Downdraft rice husk furnace |

|

|

| Fig. 3. Continuously fed furnace with cyclone combustion chamber | Fig. 4. IRRI-NLU non-grate furnace |

Table 1. Types of rice husk furnace used for paddy dryers.

|

Furnace type |

Scope of use |

Drying air efficiency |

Investment cost |

Advantages |

Disadvantages |

|

Inclined grate - cylindrical combustion chamber |

Small-scale flatbed dryers (4–20 tons batch-1) |

60 |

4–6 |

Simple, low cost maintenance |

High required labor |

|

Spraying - fed cyclone furnace |

Columnar and fluidized bed dryer with higher capacity |

50–55 |

14 |

Automatic and continuous operating; |

- Lower efficiency |

|

NLU-IRRI non-grate furnace |

Columnar and fluidized bed dryer with higher capacity |

50–55 |

4-7 |

Automatic and continuous operating; |

Lower efficiency |

|

IRRI- dRHF |

Paddy dryers (4–10 tons batch-1) |

60–80 |

5-7 |

Semi - automatic operating |

Not developed for the higher capacity yet |

References

Gummert M, Chandrasekar V, Phan HH, Nguyen TN, Ban LV, Aquino E, Rickman JF. Rice hull furnace – IRRI’s experience. Paper presented at the 5th National Grains Postproduction Conference, 18-19 July 2007, Philippines.

How steam engines work. Accessed 2015. http://science.howstuffworks.com/transport/engines-equipment/steam1.htm

Nguyen VX, Truong V, Phan HH. 1996. Development of rice husk furnaces for grain drying. http://aciar.gov.au/files/node/316/grain_drying_in_asia_part_9_11398.pdf

Nguyen VH, Nguyen TN, Tran VT, Nguyen VX, Phan HH. 2012. Rice husk uses in the Mekong Delta of Vietnam. International Workshop on the Innovative Uses of Rice Straw and Rice Husk, 11-13 December 2012. https://docs.google.com/viewer?a=v&pid=sites&srcid=aXJyaS5vcmd8cG9zdGhhdmVzdC11bml0fGd4OjcyOWMzZTg2MGUwZDZlZDU

Temples of Steam – The Rice Mills of Burma. Accessed 2015. http://www.internationalsteam.co.uk/mills/burmamill00.htm

Tran VT, Nguyen VH, Nguyen VH, Nguyen HT, Le QV, Truong QT, Phan HH. 2013. Design and development of the 10-ton/batch columnar paddy dryer. In: Proceedings of International Workshop on Agricultural Engineering and Post-harvest Technology for Asia Sustainability. Science and Technology Publishing House. p 152-163.