Grain quality

What is grain quality?

What is grain quality?

Grain quality means different things to different people depending on what they prefer. Thus, grain quality can be a combination of many factors such as smell (aroma), size, cooking characteristics, color, nutritional value, percent whole grains, etc..

Why is grain quality important?

Consumer preferences (e.g., a preference for a certain smell or whiteness of grain) affect what people buy and so affect market prices. You need to produce what the market wants.

How to maintain grain quality?

Key point: Grain moisture content is the most important factor to manage in maintaining grain quality.

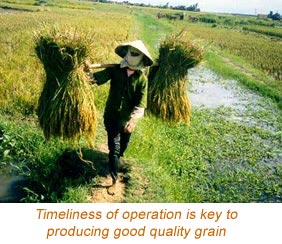

Note: Grain quality can not be improved after harvest with the possible exception that par boiling may reduce grain cracking. From the point of harvest, the rate of grain deterioration may be reduced but not stopped. It is therefore important to have a uniform harvest, on time and then have a proper system of post-harvest management that will slow grain quality deterioration.

Both good crop and post-harvest management are needed to maintain quality, increase prices and reduce losses. Steps to maintain quality:

| Factor | What to do |

| Variety | Grow varieties that meet market quality demands. |

| Crop management | Manage your field so that the crop matures uniformly. Good crop establishment, land leveling and uniform water, nutrient and pest management are important for uniform maturing of the crop. Uniformity of maturing is important as the moisture from the harvested less-mature grains can move to the dryer grains and cause grain cracking. |

| Harvest | Harvest grain at 20-25% moisture. Too wet or too dry leads to grain damage on threshing. |

| Stacking | Briefly stack harvested rice. If the crop has high moisture and temperatures are high, then rapid yellowing of the grain - even within 24hrs - can occur. |

| Threshing | Thresh promptly but at the right moisture. Too dry (less than 20%), grain will be broken during mechanical threshing leading to a lower percent of head rice. Too wet (more 25%), grain can be deformed during mechanical threshing. Manual threshing leads to less grain breakage, but can be very slow and other quality losses (e.g. fungal growth) can occur if not threshed and dried quickly. |

| Drying | Dry grain as quickly as possible to less 14% for medium term storage. |

| Grain storage | Do not mix wet grain and dry grain less than 16%. Moisture moves from the wet to the dry and this causes the dry grains to crack. |

| Milling | Mill rice at 12-14% moisture content to reduce cracking. |