Machine transplanting

What is machine transplanting of rice?

What is machine transplanting of rice?

Machine transplanting involves planting young rice seedlings into puddled soil by a machine.

Why machine transplant rice?

Machine transplanting requires considerably less time and labor than manual transplanting (1–2 ha/person/day versus 0.07 ha/person/day).

Advantages: machine transplanting

- Fast and efficient (1–2 ha/d), uses less labor and ensures timely planting.

- Reduces stress, work load, and health risks.

- Ensures uniform spacing and plant density.

- Seedlings recover fast, tiller vigorously, and mature uniformly.

How to transplant rice by machine?

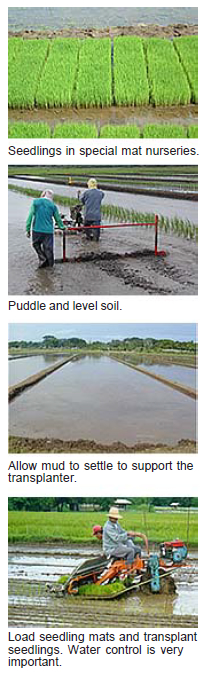

- Raise seedlings in special mat nurseries or in seedling trays. Use 18–25 kg of good seed per 100 m2 of nursery for each ha.

- Seedlings will be ready for transplanting in 12–15 days after seeding (DAS).

- Ensure that fields are well-puddled and well-leveled.

- Drain fields and allow mud to settle for 1–2 days after the final puddling.

- The subsurface soil layers need to be hard enough to support the transplanting machine.

- The soil is ready when a small “V” mark made in the puddled soil with a stick holds its shape. At this moisture level, the soil can hold the seedlings upright.

- Soil should not be so dry that it sticks to and interferes with planting parts or wheels of the transplanter.

- Load the seedling mats into the machine and transplant the seedlings at the selected machine setting.

Limitations:

- Seedlings must be planted while still young, and this makes machine transplanting a more suitable method only in irrigated areas.

- Good nursery management practices are required e.g Mat nursery & seedling trays. Special nursery management is needed (mat nursery or seedling trays).

- Proper land preparation, land leveling and water management should be there.

- Fields should be accessible for a smooth entry, exit,and tour of machines.

- Transplanting machines and its maintenance are expensive; so poor farmers cannot afford them (contract hiring of transplanters is available in some countries).

- Problems in poorly prepared and leveled land, or with poorly designed machines.

- Need of training on machine operations makes it time consuming and expensive.

Developed with input from M Bell, V Balasubramanian, and J Rickman