Fixed-bed batch dryer

What is a fixed-bed batch dryer?

A dryer is a mechanical device or machine that removes the water from wet grains by forcing either ambient air or heated air through the grain bulk. In a fixed-bed batch dryer, the same quantity of grain is kept stationary in a holding bin until drying is completed.

Why do we use fixed-bed batch dryers?

Fixed-bed batch dryers produce better grain quality than sun-drying, especially in the wet season. They are more affordable than re-circulating batch dryers of the same capacity or continuous flow dryers. They have certain advantages too:

- The simple design allows local production of the drying bin, blower and furnace and ensures easy maintenance and repair.

- It can be operated with a gasoline or diesel engine in areas where electricity is not available or very expensive.

The disadvantage is a moisture gradient that develops in the grain bulk during drying from the air inlet to the air outlet.

What are the types of fixed-bed batch dryers?

Bed configurations of fixed-bed batch dryers can either be rectangular (flat-bed dryer), inclined for better unloading, or circular.

Flat bed dryers have a simple drying bin, and a kerosene or rice hull furnace and are driven by electric motors, diesel or gasoline engines. Mixing improves grain quality. |

Typical capacity: 1-10 t/batch Typical capacity: 1-10 t/batch |

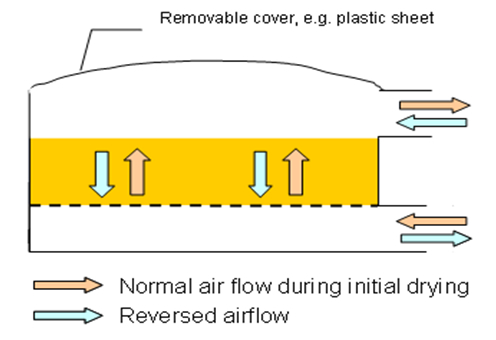

To reduce the moisture gradient and eliminate the need for mixing the airflow can be reversed in reversible flow flat bed dryers. |

. |

Circular bin dryers safe floor area and can be made from cheap materials. Drying is more uneven than in flat bed dryers. If the grain bulk is thicker than 0.4 m low-temperature drying with around 4-6°C above ambient air should be practiced. |

|

Technical specifications

Drying air temperature: <43°C

Grain depth: < 0.4 m

Air velocity: 0.15-0.3 m/s

Fan power requirement: 1.5−2.5 kW/t

For checking whether a flat-bed dryer has sufficient and even air flow: A sheet of letter sized paper placed on top of the grain must float atop the grain at all locations of the drying bin.

For more information:

Visit the Rice Knowledge Bank website (http://www.knowledgebank.irri.org), email postharvest@irri.org; or call +63 2 580 5600.